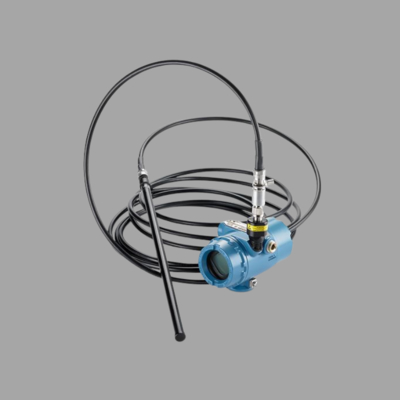

O Rosemount 702 Discrete Vortex Flowmeter representa uma solução sofisticada de medição de fluxo desenvolvida pela Emerson para medição volumétrica precisa e confiável de fluxo de vapor saturado, gás,e aplicações líquidas em ambientes industriais exigentesUtilizando os princípios fundamentais da tecnologia de descarga de vórtices,Este medidor de caudal oferece uma precisão e estabilidade excepcionais em uma ampla gama de condições de processo, mantendo requisitos mínimos de manutençãoO seu design robusto e as suas capacidades de diagnóstico avançadas tornam-no particularmente adequado para aplicações na geração de energia, no processamento de hidrocarbonetos, na fabricação de produtos químicos,e outras indústrias em que a medição do vapor é fundamental para a gestão da energia e a eficiência dos processos.

Princípio de funcionamento e base tecnológica

O Rosemount 702 opera no princípio do efeito von Kármán, onde um corpo de bluff (barra de divisão) é posicionado perpendicular ao fluxo de fluido.cria vórtices alternados nos lados a jusanteA frequência dessas separações de vórtices é diretamente proporcional à velocidade do fluxo do fluido.O medidor incorpora um sensor piezoelétrico sofisticado que detecta as variações de pressão causadas por estes vórtices sem quaisquer partes móveis em contato direto com o fluido de processoEste sinal de frequência é então processado através de algoritmos avançados de processamento de sinal digital dentro do transmissor para calcular taxas de fluxo precisas,Compensação das variações de temperatura e pressão para fornecer medições de fluxo de massa para aplicações a vaporO projecto do sistema assegura uma precisão tipicamente de ±1,0% para líquidos e ±1,5% para gás e vapor, com uma repetibilidade de ±0,2% em toda a sua gama especificada.

Características do projecto e especificações técnicas

O 702 possui uma construção robusta de carroceria de uma peça disponível em vários materiais, incluindo aço carbono e aço inoxidável, para acomodar diferentes meios de processo e condições ambientais.A sua concepção incorpora um elemento de detecção reforçado que proporciona uma resistência excepcional às vibrações e ao ruído do processoO componente do transmissor é construído com uma caixa classificada NEMA 4X/IP66, que oferece proteção completa contra a umidade, poeira,e atmosferas corrosivas. The device supports a comprehensive range of process connections from DN25 to DN300 (1" to 12") and can handle extreme process conditions with temperature ranges from -40°C to 427°C (-40°F to 800°F) and pressure ratings up to ANSI Class 900A eletrônica avançada do medidor de vazão fornece múltiplas opções de saída, incluindo 4-20 mA de saída analógica, de pulso e de alarme, ao mesmo tempo em que suporta HART® 7, FOUNDATIONTM Fieldbus,ou PROFIBUS PA protocolos de comunicação para integração perfeita em sistemas de controlo modernos.

| Categoria |

Detalhes |

| Visão geral do produto |

Alta performancemedidor de caudal de vórtice discretopara a medição volumétrica/de fluxo de massa precisa e fiável devapor, gás e líquidos saturadosem ambientes industriais exigentes. |

| Princípio de funcionamento |

- Com base noEfeito de derramamento de vórtice de von Kármán.

- Um.Corpo de bluff (barra de depósito)Gera vórtices alternados a jusante.

- Frequência de vórtice ∙ Velocidade do fluido.

-Sensor piezoelétricoDetecta variações de pressão causadas por vórtices (sem partes móveis em contacto com o fluido).

-DSP avançado (processamento digital de sinais)Calcula os caudais precisos.

- Proporcionamedição do caudal de massacom motor de pistãocompensação de temperatura e pressão.

- Precisão:±1,0% (líquidos),±1,5% (gás/vapor).

- Repetibilidade:± 0,2%. |

| Projeto e Construção |

-Corpo robusto e de uma só peçaem aço carbono ou aço inoxidável.

-Elementos de detecção reforçadosResiste às vibrações e ao ruído do processo.

-Classificação do recinto: NEMA 4X / IP66 (proteção contra umidade, poeira e corrosão).

-Conexões de processo: DN25DN300 (1"12").

-Intervalo de temperatura: -40°C a 427°C (-40°F a 800°F).

-Pressão nominal: Até à classe 900 ANSI.

-Opções de saída4 ¢ 20 mA, pulso, alarme.

-Protocolos: HART® 7, FOUNDATIONTM Fieldbus, PROFIBUS PA. |

| Vantagens de desempenho |

- Otimizado paramedição do vapor saturado.

- Integradocompensação de temperatura e pressão→ precisoFluxo de massa.

- Confiável com variáveiscomposição, densidade ou propriedades do fluido.

-Queda mínima de pressãoversus medidores de orificios/turbinas.

-Sem partes móveis→ manutenção reduzida.

-Diagnóstico avançado- monitoramento da qualidade do sinal, alertas sobre as condições do processo, verificação integrada.

-Taxa de desaceleração: Até 20:1.

- Imunidade às vibrações dos tubos. |

| Aplicações |

-Geração de energia: Monitorização da eficiência do fluxo de vapor, cálculos de desempenho.

-Processamento de hidrocarbonetos: Gases e líquidos de densidade variável.

-Indústria química: Medios corrosivos/agressivos em reactores e tubulações.

- Medição geral de vapor, gás e líquidos saturados em processos industriais agressivos. |

| Instalação e funcionamento |

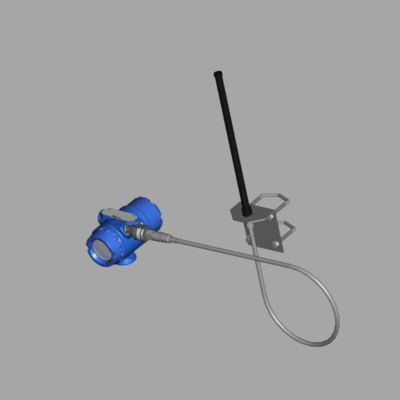

-Design compactocom montagem flexível.

- Requertubulação mínima em linha retaem comparação com outras tecnologias.

-Fácil configuração e calibraçãoatravés da interface local ou do aparelho de mão HART.

-Certificações: conformidade ATEX, IECEx, SIL 2 (aplicações críticas para a segurança). |

| Benefícios globais |

-Funcionamento preciso e sem manutençãoCom uma capacidade de alcance alargado.

-Redução do custo do ciclo de vidaversus medidores mecânicos.

-Diagnóstico e verificaçãopermitir a manutenção preditiva.

- Melhora.eficiência dos processos,Gestão da energia, efiabilidade operacional. |

Versatilidade de aplicação e vantagens de desempenho

O Rosemount 702 se destaca particularmente em aplicações de medição de vapor saturado, onde suas capacidades integradas de compensação de temperatura e pressão permitem cálculos de fluxo de massa altamente precisos.Em instalações de produção de energia, fornece dados cruciais sobre o fluxo de vapor para a monitorização da eficiência e os cálculos de desempenho.Oferece medições fiáveis de vários gases e líquidos de processo, mesmo em aplicações com composição e densidade variáveis.A construção robusta do medidor torna-o adequado para aplicações exigentes da indústria química, onde os meios corrosivos e as condições agressivas do processo são comunsO seu design de queda de pressão mínima e a ausência de partes móveis reduzem significativamente os requisitos de manutenção em comparação com as placas de orifício tradicionais ou com os medidores de turbina.O dispositivo possui diagnósticos avançados incluindo monitoramento da qualidade do sinal, alertas de condições de processo e capacidades de verificação integradas que permitem estratégias de manutenção preditivas e garantem a integridade da medição durante toda a sua vida útil operacional.

Benefícios de instalação e operação

O Rosemount 702 simplifica a instalação com seu design compacto e opções de montagem flexíveis, exigindo tubulação mínima em linha reta em comparação com outras tecnologias de fluxo.Sua interface fácil de usar permite uma fácil configuração e calibração através da interface do operador local ou através de qualquer configurador portátil compatível com o HARTA excepcional relação de deslocamento do medidor, de até 20:1, garante uma medição precisa em toda a gama de funcionamento, desde as condições de fluxo mínimo até o máximo.A fiabilidade do dispositivo é ainda melhorada pela sua imunidade às vibrações dos tubos e capacidade de manter a precisão apesar das alterações nas propriedades do fluido, tornando-a uma solução ideal para aplicações em que as condições de processo podem variar significativamente.O Rosemount 702 cumpre os requisitos de segurança e desempenho mais rigorosos para aplicações industriais críticas em todo o mundo..

Em resumo, o Rosemount 702 Discrete Vortex Flowmeter combina tecnologia avançada de eliminação de vórtices com construção robusta e eletrônica inteligente para fornecer fiabilidade,medição precisa do caudal para as aplicações industriais mais exigentesA sua operação sem manutenção, capacidades de diagnóstico abrangentes e gama versátil de aplicações tornam-na uma escolha ideal para organizações que procuram melhorar a eficiência dos processos,reduzir o consumo de energia, e melhorar a fiabilidade operacional através de dados precisos de medição de fluxo.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!

Classificação geral

Instantâneo de classificação

A seguir está a distribuição de todas as classificaçõesTodos os comentários